Rubber products are made using various technologies. One of the common manufacturing technologies of rubber products is Injection. Injection molding is used to produce rubber products for various applications. For example, at Supergum we use rubber molding to produce small items such as O-rings and V-shaped ring seals and other sealing application which are more robust products such as automotive and aerospace parts.

The injection molding process includes several steps which are illustrated in figure 1:

1. Uncured rubber in a measured amount is injected into the molding machine through a nozzle.

2. Rubber is then transferred into a heated barrel while keeping the constant pressure.

3. The heated material is injected into a heated chamber which is formed by the mold.

4. The material flows to fill in the cavities according to the product design.

5. When reached to a cured state, the mold is opened (manually or automatically) and the parts are removed (Figures 2a and 2b).

6. The parts are cleaned and optimised for use.

The injection molding is an iterative process, and the result of stages 1-6 as depicted are a single part made of rubber, then once the part is ejected from the mold, we repeat the process to create multiple parts.

Using the injection molding technology have many engineering, design and economic advantages. It allows to manufacture parts in short molding cycles, allowing the rate of production per unit to be increased. In addition, Injection leads to low cost per unit manufactured. Using the injection molding technology, we are able to manufacture shaped products and reduce the amount of rubber waste and scrap in the system, and by doing so to increase economic value and make the process more environment friendly. It is important to know that not all kinds of rubber materials fit to the use of injection molding technology. It is up to the engineers to decide on which technology to use. As for the costs, the engineer should be aware of the relative large costs of the molds themselves when using injection molding.

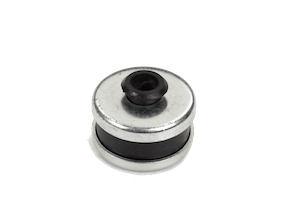

Here are some examples of the products we design and manufacture for different applications and industries using injection molding technology:

Rubber products are designed and manufactured for different and diverse industries. With each customer and application we are planning the manufacturing technology according to the needs and characteristics of the engineering challenge we deal with. For example, For conclusion, rubber injection has many advantages. However, it is not always the most cost-effective and best technology to manufacture rubber parts. It is the engineer’s job to consider the pros and cons of injection molding and deciding if other manufacturing technologies such as compression or other types of molding.